How to Overhaul the Fragile Parts of a Diesel Fuel Pump - Oil Valve Coupler

(1) Easily Worn Parts of the Oil Valve Coupler

The oil valve coupler consists of several parts that are prone to wear. Among them, the sealing cone and the pressure-reducing ring are particularly vulnerable. The sealing cone surface and the vacuum ring are especially susceptible to damage. Additionally, the seat area is also an easy-to-wear component, specifically the sealing cone and the guide hole.

(2) Effects of Wear on the Oil Valve Coupler

When the sealing components of the oil valve coupling become worn, the overall sealing performance deteriorates. During the operation of the fuel injection pump, some diesel fuel from the high-pressure fuel line may flow into the plunger sleeve. This leads to a significant drop in high-pressure fuel pressure when fuel supply stops. When the fuel injection pump operates again, the diesel fuel must be pressurized from low to high, causing a delay in the injection timing and a corresponding reduction in fuel delivery volume.

If the decompression ring is worn, the gap between it and the seat hole increases, resulting in reduced lift during the fuel supply process. This weakens the pressure reduction effect, causing the remaining diesel in the high-pressure fuel line to increase after the fuel pump stops supplying fuel. As a result, fuel delivery may increase, leading to unstable engine operation, loss of power, and increased fuel consumption.

(3) Visual Inspection Items and Sealing Test Methods

When inspecting the oil valve coupler parts, the following visual checks should be performed:

â‘ The oil relief ring must not show any obvious signs of wear.

â‘¡ The outer surface of the sealing cone must not have significant wear, metal scraping, or longitudinal scratches.

â‘¢ The conical surfaces of the valve and the valve seat must not exhibit noticeable corrosion.

(4) Inspection and Repair Methods for the Oil Valve Coupler

â‘ Sliding Test Method: Clean the oil valve coupler parts and place them vertically. Then, immerse the valve in the oil pan up to half its width. Rotate the valve at any angle. If the valve can freely fall back to the seat under its own weight, it is considered qualified. If it gets stuck during the sliding process, it is deemed unqualified.

â‘¡ Repair Method: If the sealing performance of the valve cone is poor, the valve can be placed on a grinding machine. Apply a thin layer of abrasive paste to the sealing cone and manually hold the valve and seat together while operating the grinding machine. If a grinding machine is unavailable, a manual grinding method can be used instead.

Regular maintenance and timely replacement of these critical components are essential to ensure the proper functioning of the diesel fuel pump and maintain engine efficiency.

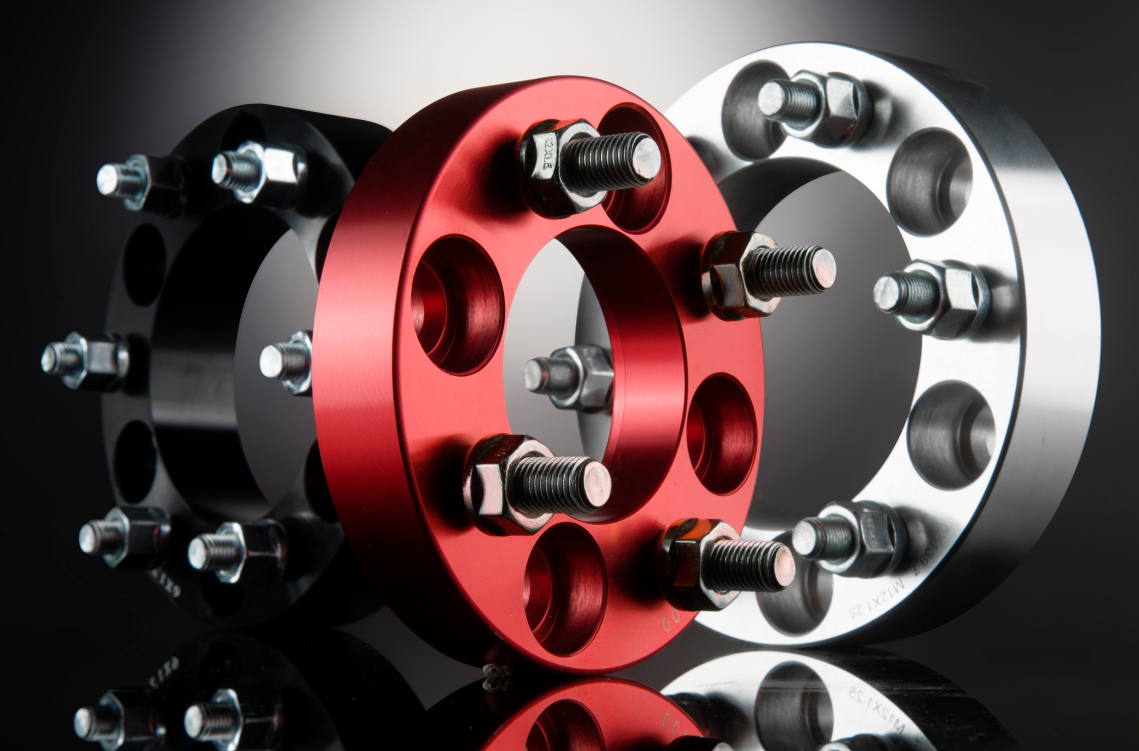

Yokelink providing high-quality wheel accessories, including Wheel boltss, Wheel nuts and Wheel spacers. Wheel spacers are essential components that are used to create additional space between the wheel hub assembly and the wheel. They are designed to improve vehicle stability, enhance handling, and allow for the installation of larger tires.

Wheel Accessories,Wheel Lug Nuts,Truck Wheel Spacers,Chrome Wheel Nuts,Aluminum Alloy,Wheel Spacers

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com