Pipe beveling joints are fundamental in many industries, playing a key role in creating robust and efficient connections between pipes. As we explore various types of these joints in this post, we’ll also look at how they’re applied across different sectors. By understanding the unique features and benefits of each type, industries can make well-informed choices to optimize their welding outcomes.

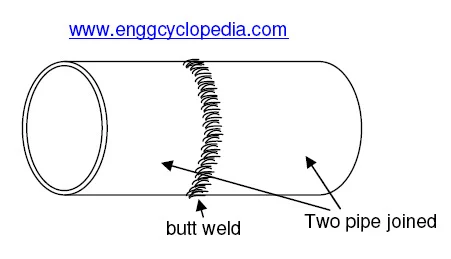

Let’s start with the **butt joint**, one of the most straightforward and commonly used pipe beveling joints. It connects two pipes end-to-end, offering simplicity and ease of welding. This joint is widely used in construction, plumbing, and the oil and gas industries because of its ability to create a smooth, continuous surface that facilitates uninterrupted fluid or gas flow.

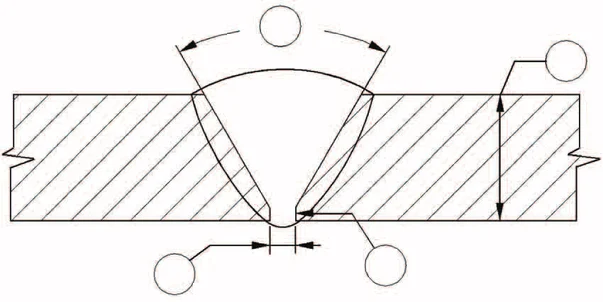

Next up is the **V-groove joint**, which features a V-shaped groove at the pipe ends. This design promotes deeper penetration of the welding material, making it ideal for industries like shipbuilding and structural steel fabrication. The V-groove joint offers enhanced strength and weld quality, making it perfect for applications where reliability is paramount.

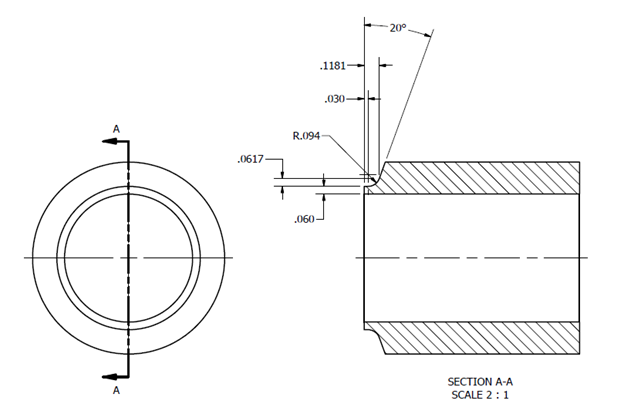

Moving on, the **J-groove joint (or J-prep)** provides a J-shaped groove that creates a smooth internal surface, minimizing contamination risks. Food and beverage processing, along with pharmaceutical industries, frequently use J-groove joints due to their hygiene-focused requirements. These joints not only maintain the integrity of the piping system but also simplify cleaning and maintenance processes.

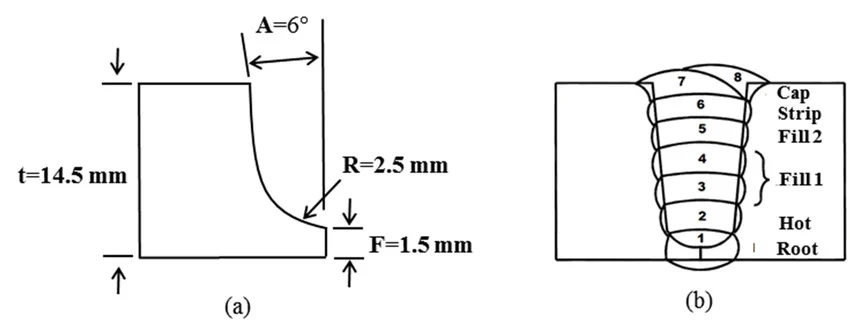

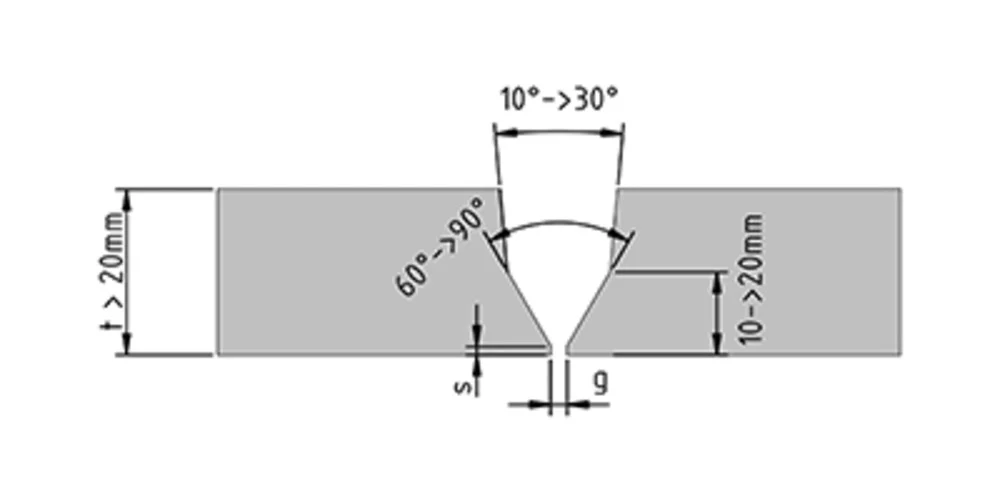

For situations where access for welding and inspection is limited, the **U-groove joint** comes into play. With its U-shaped groove, welders can reach challenging areas and ensure a solid connection. Pipeline construction and maintenance teams often turn to U-groove joints to address spatial limitations while maintaining pipeline integrity.

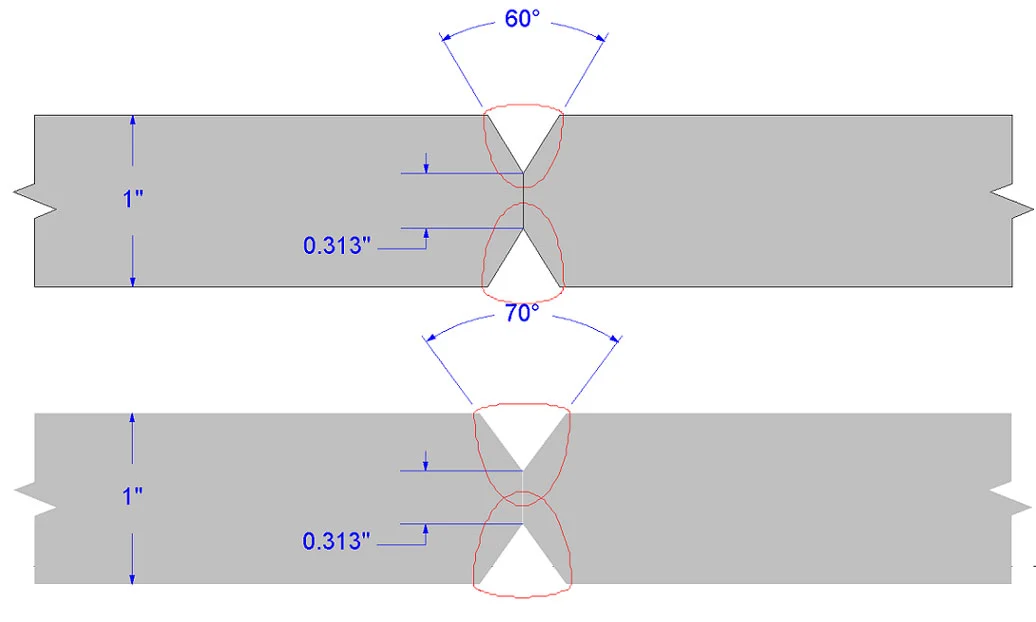

When dealing with high-stress environments, the **double V-groove joint** stands out for its exceptional strength and load-bearing capacity. Industries such as pressure vessel fabrication and heavy machinery manufacturing benefit greatly from the robustness and structural integrity provided by this joint type.

Lastly, the **compound bevel joint** combines multiple bevel angles to achieve precise alignment and fitment. Aerospace and automotive manufacturers rely on compound bevel joints to meet complex geometrical demands and ensure peak performance in their components.

Understanding the distinctions between these pipe beveling joints and their respective applications is vital for executing successful welding projects. By carefully selecting the right joint for your needs, you can guarantee strong connections, efficient flow, and top-tier performance in your piping systems. Whether it’s a basic butt joint for simpler setups or a sophisticated compound bevel joint for intricate tasks, choosing the appropriate pipe beveling joint is key to achieving superior welding results.

Lever Locks,Privacy Door Lever Set,Zinc Cylinderical Door Handle,Door Handle With Keyless Lock

ONLEE HARDWARE CO.,LTD , https://www.onleehardware.com