Load Links, also known as dynamometers, are specialized load cells designed to measure both static and dynamic loads when tensioned between two points, typically using shackles. These versatile tools find applications across a wide range of industries, including heavy lifting, entertainment, and towing. Essentially, whenever opposing tensions are applied between two points, a Load Link can be employed effectively.

Wired vs Wireless Load Links: Which One Fits Your Needs?

When it comes to Load Links, the primary distinction lies between wired and wireless options. Wired Load Links are often favored in scenarios where the load cell remains fixed in place, such as in permanent installations or products where mobility isn’t a concern. For instance, in sensitive environments like military or nuclear operations, wired solutions are sometimes preferred to avoid potential interference from wireless technology, even though such issues are rare. Wired Load Links can be used individually or in groups to monitor different parts of an application. With cable lengths extending up to 1500 meters, these Load Links are ideal for large-scale structures and long-distance monitoring. Additionally, our StraightPoint wired Load Links can be easily integrated with wireless transmitters, allowing data transmission without physical wires. This setup enables remote control of functions like ‘tare’, ‘on/off’, and overload alarms through handheld devices, computers, smartphones, or PLCs.

On the other hand, Wireless Load Links dominate the market due to their flexibility and convenience. Without the hassle of cables, they’re perfect for on-site lifts involving complex rigging and multiple monitoring points. Like their wired counterparts, wireless Load Links can be used independently or in clusters to measure tension at various locations. The hiring industry particularly appreciates their portability, quick setup, and reduced risk of damage during transportation. Thanks to advanced technology, wireless Load Links can now connect seamlessly with PLCs, tablets, PCs, and smartphones, offering more than just basic handheld controls. They also come equipped with built-in displays showing the current load, along with easy-to-use buttons for features like ‘tare’ (to reset weights), ‘on/off’, and overload alerts. Concerned about range? Our StraightPoint wireless Load Links boast an impressive wireless range of up to 700 meters. And don’t worry about frequent battery changes—four AA batteries can keep these Load Links running for approximately 1200 hours.

Both wired and wireless Load Links serve critical roles depending on the application. Whether you need precise measurements in a stable environment or flexible solutions for dynamic setups, Load Links provide reliable performance tailored to your needs.

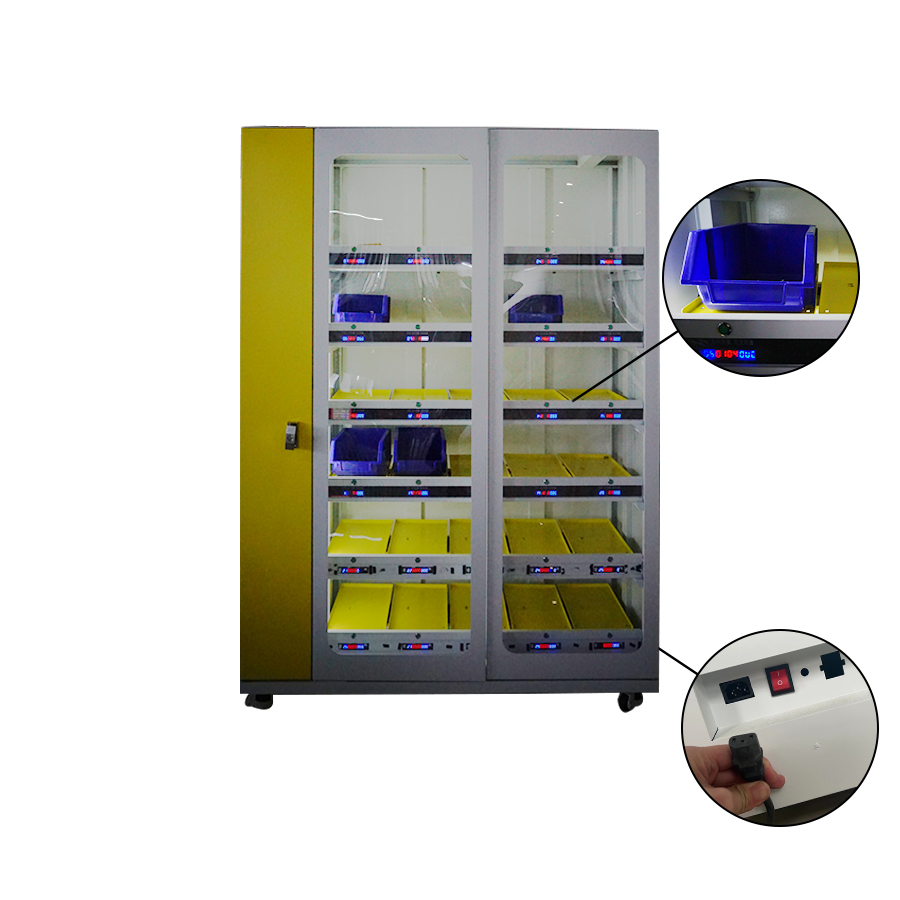

Weighing Cabinet

Enclosure: Weighing cabinets create a contained environment around the weighing balance, preventing hazardous materials from escaping into the laboratory.

Ventilation: Most weighing cabinets are equipped with ventilation systems that draw air into the cabinet, filter it, and exhaust it to the outside or recirculate it within the cabinet. This helps to maintain a safe and clean working environment.

Safety glass: The front panel of a weighing cabinet is typically made of safety glass to provide visibility while protecting the operator from potential hazards.

Ergonomic design: Weighing cabinets are designed to be comfortable and easy to use, with features such as adjustable height and tilt.

Built-in features: Some weighing cabinets may have additional features, such as built-in lighting, power outlets, and storage compartments.

Benefits:

Safety: Weighing cabinets protect the operator and the laboratory environment from exposure to hazardous materials.

Accuracy: The controlled environment within a weighing cabinet can help to ensure accurate and precise weighing results.

Compliance: Weighing cabinets are often required to comply with safety regulations and standards in industries such as pharmaceuticals, chemicals, and research.

Efficiency: By providing a dedicated space for weighing operations, weighing cabinets can improve efficiency and productivity in the laboratory.

Applications:

Pharmaceutical industry: Weighing cabinets are essential for handling and measuring pharmaceutical ingredients, ensuring product quality and safety.

Chemical laboratories: These cabinets are used for weighing chemicals and other hazardous substances in research and development settings.

Research laboratories: Weighing cabinets are valuable tools for scientists conducting various experiments and analyses.

Quality control: In industries where precision weighing is critical, such as food and beverage manufacturing, weighing cabinets are used for quality control purposes.

Types of Weighing Cabinets:

Standard weighing cabinets: These are general-purpose cabinets suitable for a wide range of applications.

Powder weighing cabinets: Designed specifically for handling powders, these cabinets often have specialized ventilation systems to prevent the spread of airborne particles.

Hazardous substance weighing cabinets: These cabinets are equipped with advanced safety features to protect operators from exposure to highly toxic or hazardous substances.

Factors to Consider When Choosing a Weighing Cabinet:

Safety requirements: Consider the specific hazards associated with the materials you will be handling and choose a cabinet that meets the appropriate safety standards.

Ventilation system: Evaluate the ventilation system to ensure it is adequate for your needs and complies with relevant regulations.

Size and capacity: Select a cabinet that is large enough to accommodate your weighing equipment and the materials you will be handling.

Ergonomics: Ensure that the cabinet's design is comfortable and ergonomic for the operator.

Additional features: Consider any additional features that may be beneficial, such as built-in lighting or power outlets.

By investing in a high-quality weighing cabinet, you can create a safe and controlled environment for your precision weighing operations, ensuring accurate results and protecting the health and safety of laboratory personnel.

Product color: White yellow (customizable)

Capacity: 30 scales

Freight lane type: 6 floors * 5 lanes

Weighing sensor: A single weighing position can weigh up to 20 kg, a small weighing capacity of 5g, and an error of 1gram

Applicable system: optional card swiping, facial recognition, and fingerprint recognition

Power supply: AC220V/50HZ

tool tracking, hazardous materials, precision weighing

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com