According to reports from the physicists' organization network, the German Fraunhofer Institute for Solar Energy Systems, French concentrator photovoltaic manufacturer Soitec, and the Helmholtz Research Center in Berlin have made a groundbreaking achievement. They announced that they've developed a solar cell with a light concentration of 297 and a photovoltaic conversion efficiency of 44.7%, setting a new world record. This breakthrough is expected to significantly cut the cost of solar energy and bring us closer to achieving 50% efficiency in solar cells.

This isn't the first time this team has pushed the boundaries of solar technology. Earlier this year, in May, these same organizations, along with scientists from the CEA-Leti laboratory in France, achieved a record 43.6% efficiency under a concentration of 319. Building on that success, researchers have refined their methods, optimized performance, and ultimately produced the latest version with an impressive 44.7% efficiency.

These advanced solar cells are primarily used in concentrating photovoltaic (CPV) systems. CPV technology uses optical elements like lenses or mirrors to focus sunlight onto high-efficiency photovoltaic cells, converting it directly into electricity. This method is considered one of the most promising third-generation solar technologies, offering greater efficiency and scalability compared to traditional silicon-based panels.

The newly developed four-junction solar cells are constructed using different III-V semiconductor materials—such as gallium, indium, nitrogen, and phosphorus—each selected for its ability to capture specific parts of the solar spectrum. By stacking these materials, each subcell can efficiently convert a different wavelength of light, resulting in higher overall efficiency.

Frank Demers, head of R&D at the Fraunhofer Institute for Solar Energy Systems, highlighted the long-term effort behind this achievement. "For years, we've been working on multi-junction solar cells," he said. "This four-junction design is the result of many years of research, not only improving materials and structures but also introducing a new technique called 'wafer bonding.' This allows us to precisely combine two semiconductor crystals, creating the best possible configuration for maximum efficiency."

Andrei Jacqueliman, CEO of Soitec, expressed optimism about the future of the technology. "In just four months, the efficiency record increased by 1%, which shows the immense potential of four-junction solar cells," he said. "I believe we're on the verge of breaking the 50% efficiency barrier soon." With continued innovation and collaboration, the path to ultra-efficient solar power is becoming clearer every day.

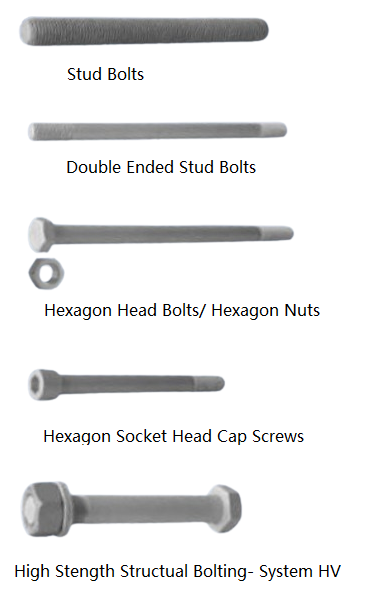

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

WHAT ARE WINDMILL POWER FASTENERS?

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Wind mill ,Wind Power fasteners, Wind mill Turbine, Stud Bolt, windmill energy, house wind turbine, Wind Turbine Blades

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com